Production Process

-

1. FLANGE RAW MATERIAL PROCUREMENT

1. FLANGE RAW MATERIAL PROCUREMENT

Raw materials, including billets and bars are imported from Sweden and Japan.

-

2. FLANGE MATERIAL TESTING

2. FLANGE MATERIAL TESTING

Samples of material from each heat NO. are subjected to random testing to keep accurate records for the different types of materials imported.

-

3. FLANGE MATERIAL CUTTING

3. FLANGE MATERIAL CUTTING

Raw material is cut by cutting machines based on requested weight.

-

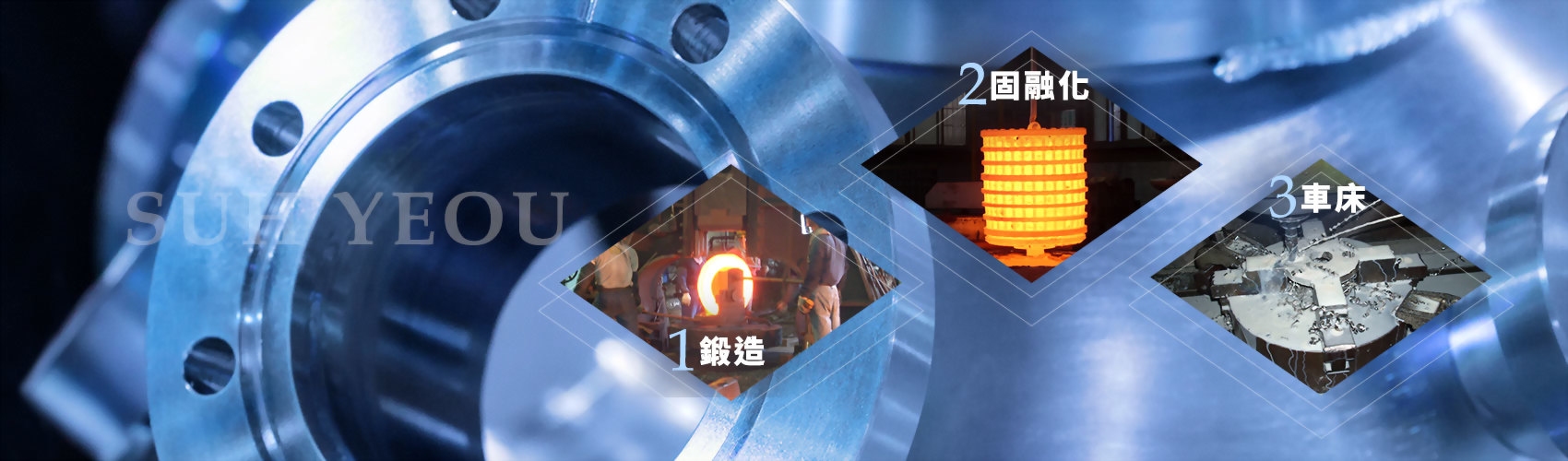

4. FLANGE MATERIAL FORGING

4. FLANGE MATERIAL FORGING

Cut Material is heated and forged.

-

5. QUALITY CONTROL FOR SEMI-FINISHED FLANGES

5. QUALITY CONTROL FOR SEMI-FINISHED FLANGES

Material is retested and sizes are checked.

-

6. SEMI-FINISHED FLANGES SOLUTION TREATMENT

6. SEMI-FINISHED FLANGES SOLUTION TREATMENT

Solution treatment is done to make sure the chemical components of materials have returned to the original structure.

-

7. SEMI-FINISHED FLANGES STORAGE

7. SEMI-FINISHED FLANGES STORAGE

Storing and classifying all types of Semi-finished flanges by colors.

-

8. FLANGE MACHINING

8. FLANGE MACHINING

Flanges are machined based on exact sizes.

-

9. FLANGE DRILLING

9. FLANGE DRILLING

Flanges are drilled into finished products based on exact sizes.

-

10. CHECKING THE SIZE OF FINISHED FLANGES

10. CHECKING THE SIZE OF FINISHED FLANGES

Checking the size of finished flanges to ensure it is correct.

-

11. QUALITY CONTROL FOR FINISHED FLANGES

11. QUALITY CONTROL FOR FINISHED FLANGES

Check the quality of finished flanges by Visual Inspection and dyeing.

-

12. FINISHED FLANGES CLEANING

12. FINISHED FLANGES CLEANING

Cleaning the finished flanges.

-

13. FLANGE MARKING

13. FLANGE MARKING

Company name, nominal size,nominal pressure and material are marked on the outside flange for identification.

-

14. FINISHED FLANGES STORAGE

14. FINISHED FLANGES STORAGE

Storing the quality checked flanges depends on the size and material.

-

15. FLANGE PACKING & SHIPPING

15. FLANGE PACKING & SHIPPING

Flanges are packed and shipped to specified destinations.